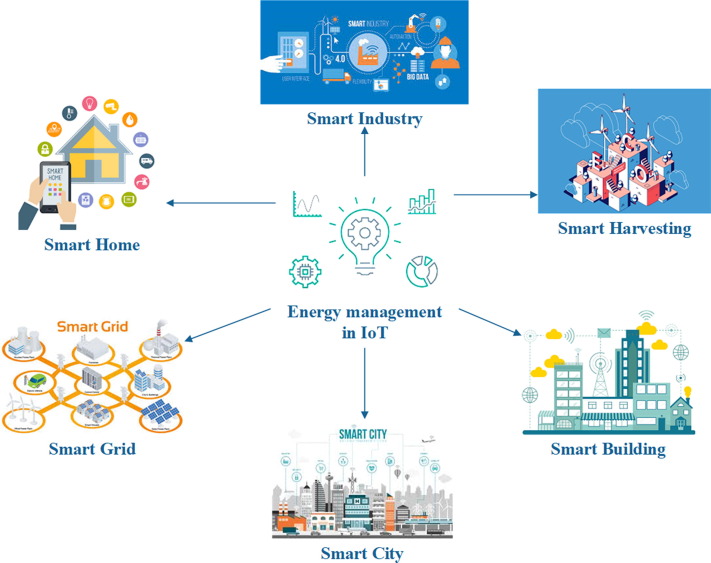

Industrial IoT platform enables any industrial company to accelerate its digital journey and improve operational efficiency by 20-30%. With best-in-class solutions, expertise and partnerships, we are a one-stop-shop for implementation and management of Industry 4.0 programs for your enterprise.

Industrial IoT offers great promise for new digital service business as well as more efficient production and maintenance.

Smart & Continuous Power Consumption Monitoring

Installed Schneider Energy Meters and configured Power Monitoring Expert Software v8.2 to support Maintenance team in smart & continuous Power Consumption Monitoring, Meter Data Acquisition into an SQL Database.

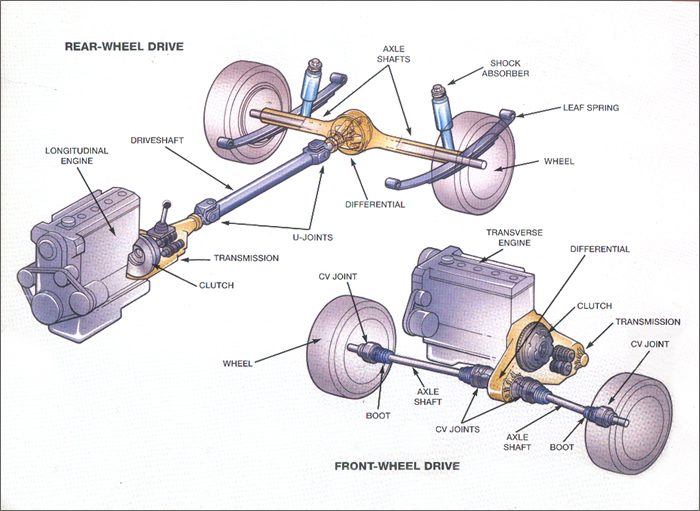

Global Manufacturer of Axles, Driveshafts & Drive Train Products

Challenge of End-to-End traceability, Prevent Part Mixup, Monitor & Control Quality. Solution was RFID & Barcode integration for product identification and traceability, Multi gauging integration with auto tool-offset compensation, SAP integration for picking, packing and dispatch. Achieved 100% Production Identification and Traceability for all products moving through the factory floor from incoming material to final despatch to the customer.

Indias Largest Aluminium Die Casting parts Manufacturer

Challenge of To get accurate OEE, To monitor production output in real-time, Traceability, Monitor Inventory Levels. Solution was Real-time production monitoring, Auto Downtime capture, Integration with SAP inventory module, Auto capture of Process Parameters. Achieved 100% visibility for real-time production monitoring resulting in accurate inventory management in SAP.

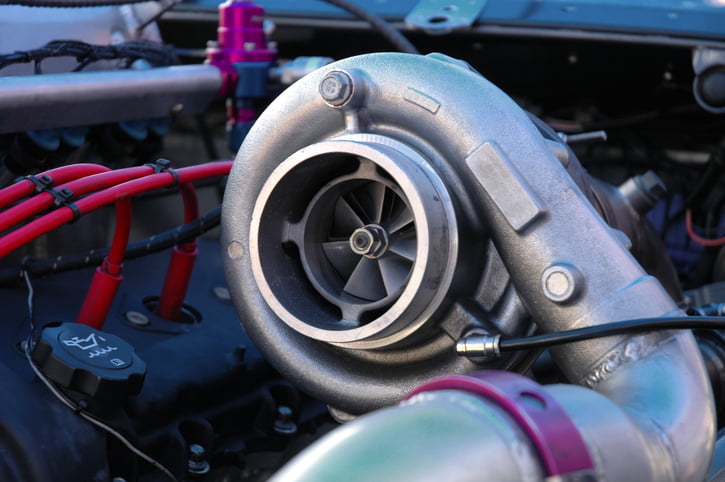

Leading Turbo charger Manufacturer

Challenge was Standardisation of documentation and processes, Digital and Paperless shopfloor, Track Operator Efficiency. Solution was Integrated and connected to 350+ machines to ensure discipline, RFID based operator authorization. Achieved 100% system compliance with complete Operator Traceability resulting in increase in OEE by 25%. Currently monitoring 350+ machines across all units. Plans now in place to replicate this success across group companies.

Manufacturer of Connectivity and Sensors and Electronic components

Challenge was Prevent over-production on injection moulding machines, Paperless shopfloor, Live Production Monitoring. Solution was integrated with injection moulding machines, Kiosk based task manager, ANDON for live machine status and production monitoring. Prevented over production to the tune of 6% resulting in additional free capacity. Currently deployed across all moulding machines with plans to horizontally deploy across other manufacturing processes within the organization.

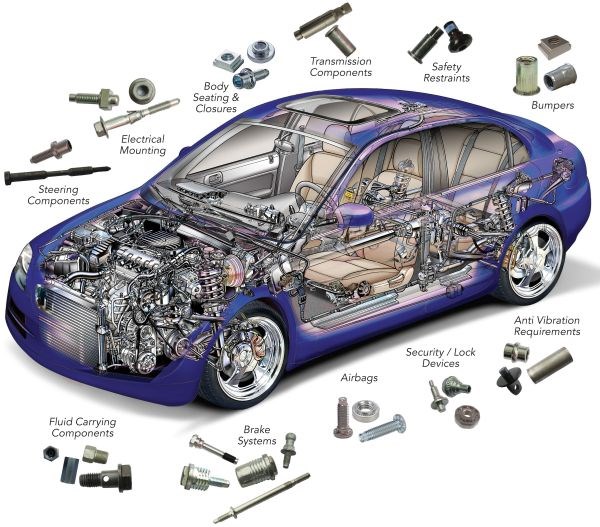

Leading Manufacturer of Fasteners for Automotive Industry

Challenge was Track & Trace, reduce in-process inventory, Standardise quality documents for thousands of SKUs. Solution was Live tracking of WIP inventory at every stage, Production ANDON, Digital work instruction & checksheets with instrument/gauge integration, Batch traceability from RM to FG